🧰 Maintenance Guide for True Beadlock Wheels

🧰 Maintenance Guide for True Beadlock Wheels

True beadlock wheels are incredible for low-PSI traction — but they require a bit more care than standard or beadlock-style wheels. This guide explains how to keep beadlocks structurally sound, airtight, and adventure-ready.

🔩 Routine Maintenance — After Every Off-Road Trip

Beadlocks take stress from impact, torsion and low tyre pressure. After running them hard:

-

Check for bolt loosening

-

Inspect outer ring for damage

-

Look for mud, sand or grit around the bead

-

Confirm tyre bead hasn’t shifted

-

Verify tyre PSI after bead compression

-

Spin test — check for wobble or run-out

Even one loose ring bolt can put uneven pressure on the bead — risking leaks or tyre failure.

🔧 Torque & Bolt Management

Torque is everything.

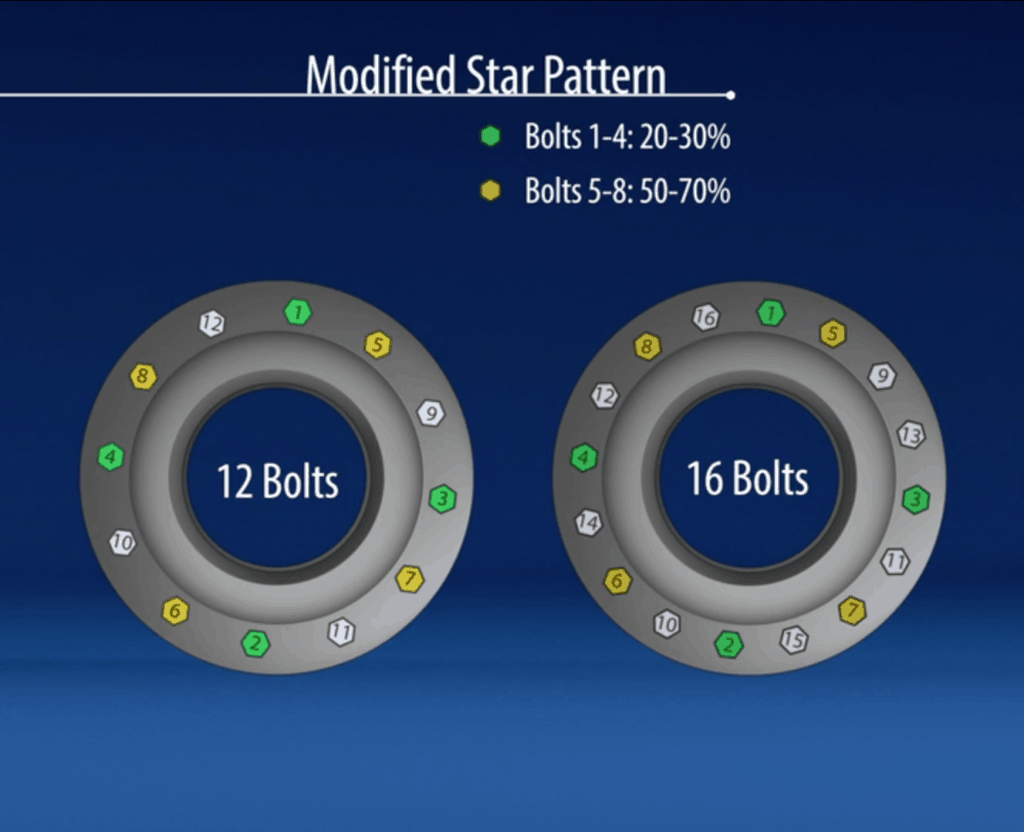

Always tighten bolts in a cross-/star-pattern.

Typical torque range:

🔧 18–22 ft-lbs (24–30 Nm)

(Always check manufacturer specs — KMC, Method, Dirty Life may vary)

Best practices:

✔ Use a torque wrench — never “by feel”

✔ Do NOT use impact guns on final tightening

✔ Retorque after the first 50–100 km of driving

✔ Retorque after airing down and reinflating

🛢️ Cleaning & Corrosion Prevention

Road salt, mud and sand can creep under the beadlock ring.

Best cleaning practices:

-

Remove ring if needed

-

Clean mating surfaces

-

Clear debris from bolt holes

-

Use non-acidic wheel cleaners

-

Avoid corrosive chemicals

Optional for longevity:

✔ Anti-seize paste on bolt threads

✔ Light silicone bead on tyre edge if recommended

🚨 Signs Your Beadlocks Need Attention

You may have a problem if:

❗ You hear clicking at low speed

❗ Bolts are backing out

❗ Tyre loses PSI overnight

❗ Visible bead separation

❗ Mud/water is weeping from bead edge

❗ Ring looks warped or bent

If you hit rocks, stumps or ledges hard — inspect visually every time.

🧪 PSI & Tyre Behaviour — Running Low Pressure Safely

Low PSI is the primary benefit of beadlocks — but only within limits.

Recommended safe operating low-PSI ranges:

-

Sand: 10–14 psi

-

Rock crawling: 8–12 psi

-

Mud: 12–15 psi

-

Snow: 8–12 psi

Below 8 PSI, tyre carcass distortion increases dramatically — only recommended for experienced operators.

⚙️ Spare Hardware & Replacement Components

It’s smart to carry:

-

spare ring bolts

-

extra washers

-

small torque wrench

-

valve cores

-

bead lubricant

-

small wire brush

A single damaged bolt can compromise the entire ring tension.

🏁 Final Maintenance Philosophy

Beadlocks aren’t “set and forget.” They’re high-performance components that work under high stress. Treat them like part of a race vehicle:

-

Inspect regularly

-

Retorque consistently

-

Clean thoroughly

-

Respect PSI limits

-

Replace damaged bolts immediately